Choose your country or region

- Europe

- Spain

- Catalonia

- Portugal

- United Kingdom

- International Version

Rice fields

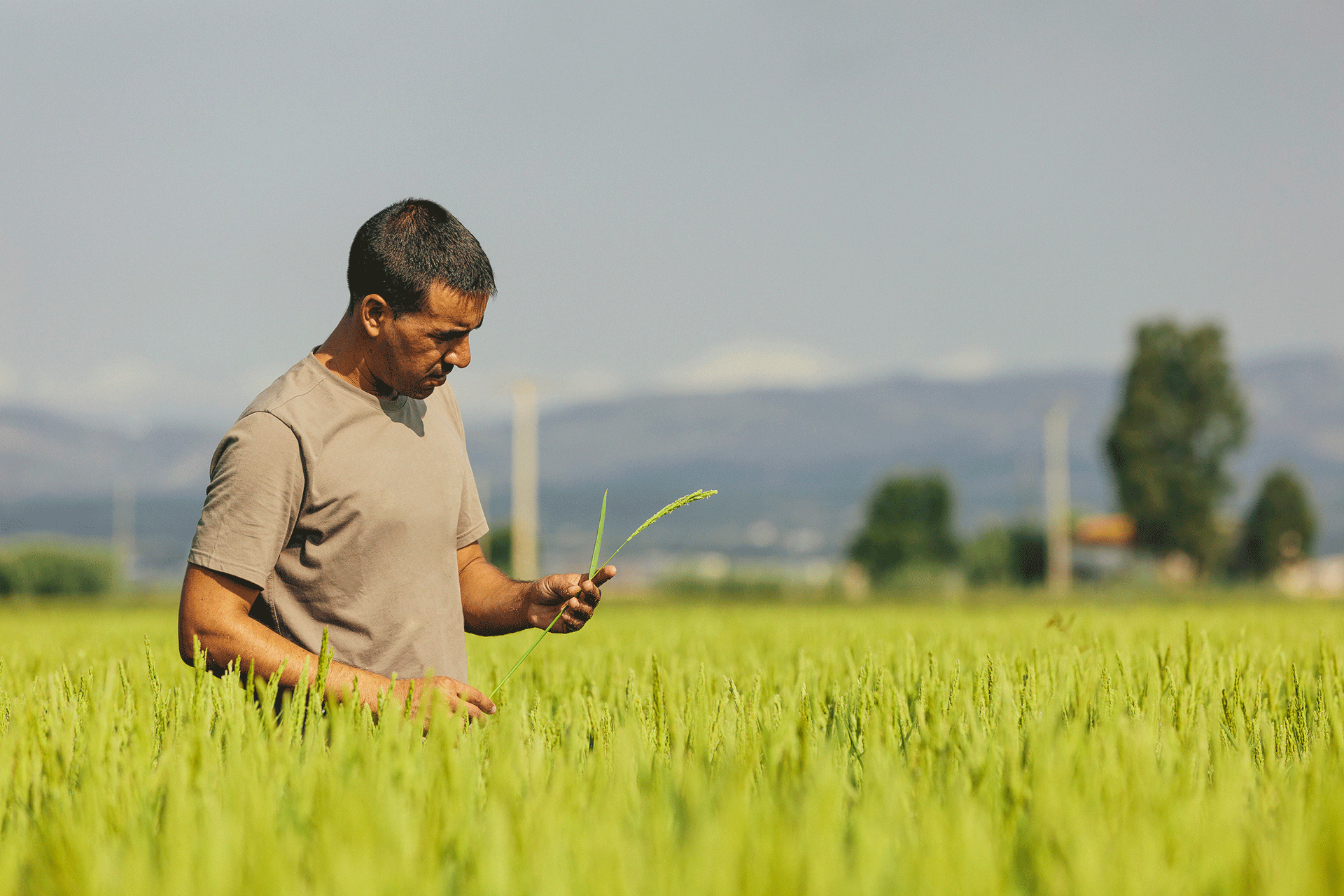

Flowering and pollen: this is how rice comes into being

8:41 h — In August, the atmosphere at the rice fields in Delta de l’Ebre is extremely humid, busy with mosquitoes and stifling hot. Of course, discomfort is the price we have to pay to achieve the perfect conditions to grow rice, one of the ingredients of our Estrella Damm. And this time of year is, precisely, the most decisive: now is when the flowering period and the subsequent pollination of the ears begin. J. Casanova, a local agricultural technician, tells us that the flowering period started in late July, and that “once the ears are pollinated, the grain starts to grow inside them”. When this happens, the ear becomes heavier and heavier until it ends up bending downward. This bending, along with the yellow colour of the plants, will show us when is the time for harvesting, which is expected to happen in early September.

“Once the ears are pollinated, the grain starts to grow inside them”

J. Casanova

La Moràvia malt house

The toasting process warms the malt house up

13:50 h — This August, the heat is being unforgiving in Lleida, which is home to La Moràvia, our malt house. Luckily, though, the outside temperature is nowhere as near the temperature to which the barley is subjected in our sprouting and drying rooms, especially when it’s time to toast the sprouted grains. This is the last stage of the malting process, which, according to La Moràvia’s director, T. Ramo, “gives the malt its flavour and helps remove the small root that grows during the sprouting.” Thee hours at 85ºC leave the barley, now turned into malt, ready to be cleaned and brought to the factory. Given its extreme temperature, the room stays closed through the whole process. Moreover, the pressure of the air inside it would make it impossible to enter it. Who would want to get toasted in a room at 85ºC like barley being malted, anyway?

“The toasting process is what gives the malt its flavour”

T. Ramo

Damm Factory

Pasteurisation to preserve the beer

17:23 h — Protecting the flavour and the properties of the beer is a top priority at our factory… but then, so is making it using only natural ingredients that are free of additives. That is why it is pasteurised: it is the best way to preserve the beer for longer and to eliminate any possible microorganisms without altering the original recipe. But how is that done? This process is easier than it seems. Like D. Sancho, head of the packing division, tells us, “Pasteurisation is a lot like stepping into a giant shower.” And it’s true: the process involves sealing the bottles for an hour and putting them into water at different temperatures, which gradually increase until reaching 60ºC. “It is important to do it gradually to prevent the bottles from breaking, and not to keep them in there for too long or at too high temperatures in order to avoid the oxidising of the product”, says Sancho, who monitors the process from start to finish. Because when it’s about protecting the beer… there’s no margin for contingencies.

“Pasteurisation is a lot like stepping into a giant shower”

D. Sancho